Listen here:

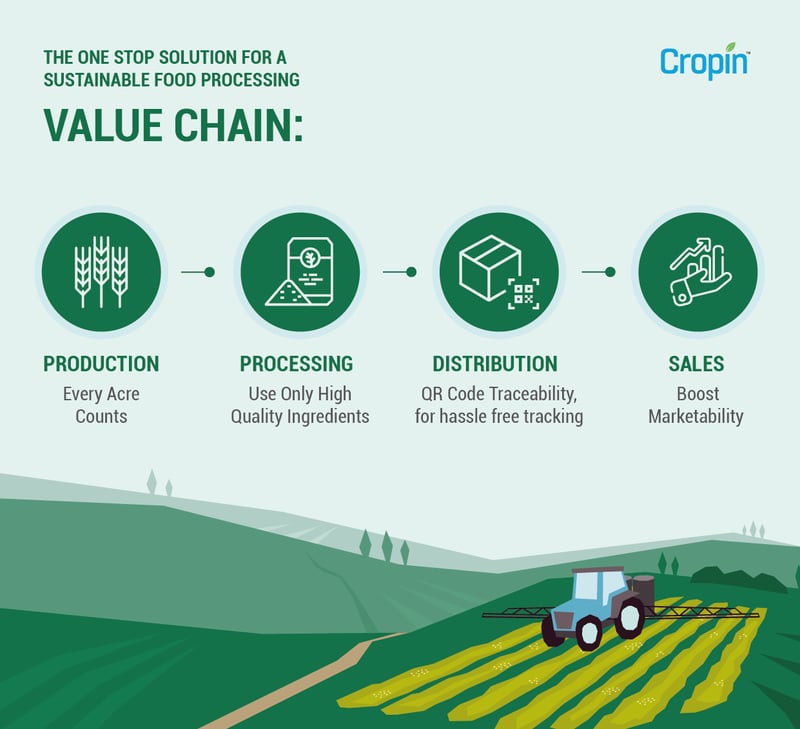

The bedrock of any reputable food brand in the market is the quality of the raw materials it sources. As raw materials progress through the value chain from the farm to the consumer’s table, it undergoes numerous steps of processing and value addition before it is fit for consumption. IoT in food industry is transforming the way the supplies or resources are traced from the source until processing.

However, the current value chain in the food processing industry is inefficient and almost always results in a loss of nutrition as it progresses through the chain. In a time of climate crisis, threatened food security, and population explosion, it becomes imperative to reduce waste, improve traceability, and maximize output by creating a sustainable value chain for food processing.

With world hunger on the rise (an estimated 1/3rd of the food produced is wasted), exploring new avenues to decrease wastage whenever and wherever possible starts with the food processing value chain. With the vision to provide consumers around the world with high-quality products and the mission to drive sustainable practices and propel innovations, food processing companies have to wake up to the real threat of imperiled food security and the massive economic gains of a data-driven, sustainable value chain.

Given the interconnectedness of the global supply chain and the thin thread that our ecosystem hangs off, the industry requires a data-driven approach to tackle these problems and ensure a smooth transition of raw materials from one stage to the next, with minimal wastage, and preserve the environment consciously.

How to Ensure an Impeccable Production?

The brand value in a fundamental sense hinges upon the quality of the raw materials used for production. For obtaining the best possible output, food processing companies constantly monitor key performance indicators like a number of non-compliance events (events that deviate from regulatory requirements), estimated yield, and reject ratio (scrap being the inherent aspect of production and productivity. The traditional norm of measuring these KPIs hasn’t proven to be very successful, given the high wastage rate and low-quality output obtained.

Image Credits: https://qz.com/

Image Credits: https://qz.com/

The Chinese Milk Scandal of 2008 rocked the food industry. Milk, milk powder, and baby formula were laced with fatal quantities of melamine (a plastic, known for its flame retardant properties), which led to tragic consequences. To this day, it is not determined where this chemical was added in the value chain, which is problematic because it exposes a huge loophole in the production and processing stages increasing the chance of adulteration. Now almost 12 years later, denizens do not trust local milk and milk products and opt for non-local options.

The 2013 Horsemeat Scandal was another major lapse in processing that adversely affected the brand image and upset the beef market in Europe. Mislabeled processed meats were sold in the UK, the Republic of Ireland, France, Norway, Austria, Switzerland, Sweden, and Germany. Many investigations even revealed the presence of pork. With a diverse population in the EU, eating pork is prohibited in some communities, and customers throughout the continent were appalled by these standards, calling to question the integrity of the food processing value chain.

All these examples highlight the importance of maintaining an impeccable and fool-proof value chain that does not violate consumer trust in the brand or product.

Needless to say, in order to engineer a water-tight value chain, companies must start by sourcing and procuring from reliable and consistent producers/farmers. To ensure the best quality raw materials, food processing companies must ensure traceability, accountability, and source raw materials from farmers with a history of high-yield delivery and maintain strict compliance with industry standards.

Regulatory Authorities and Legislators want food processing companies to move towards a digital practice like the one followed in the Pharmaceutical and E-Commerce industries to ensure better data management for optimal transparency and traceability. This move comes in part to Smarter Food Safety, which is "Technology Enabled” and promotes a food safety culture. Consumers are becoming more skeptical and want to know where their products come from, and whether they’ve been processed and delivered as advertised.

Issues like low farm productivity, high seasonality, fragmented holdings, and perishability result in the lack of distribution of supply and quality, and in turn, impede processing and exports. The most pertinent issue being a decline in yields and the consequent reduction in crop quality, safeguarding future crops becomes the top priority.

A prominent beverage company needed accurate reports and insights on the production of priority raw materials viz barley, maize, sugar, sorghum, agave, and aniseed. With a large global presence, this company faced the challenges of ensuring that the sources were free from environmental and social risks and aimed to build better sustainability by incorporating best practices to maximize output quality.

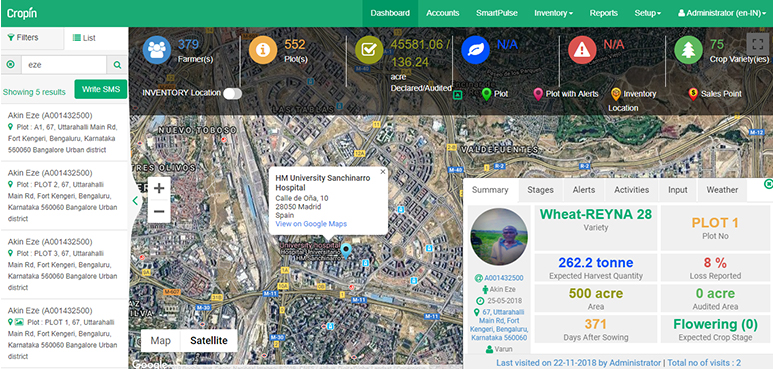

Cropin provides a full-stack Agtech Platform that delivers cutting-edge solutions for every stakeholder in the ecosystem. Leverage our satellite monitoring capabilities for crop detection and obtain accurate weather analysis and advisories to mitigate any risk and boost output.

Cropin’s SmartFarm is a state-of-the-art farm management solution, the solution enables farmers to capture several parameters through every stage of production and monitor them systematically to increase productivity at every stage of production.

Increase efficiency and strengthen sustainability by obtaining periodic and valuable insights on crop health, pest infestation, crop growth, and output predictability with our cutting-edge algorithms, establish a data-driven practice to make the best possible decision, and procure only the highest quality crop.

Cropin has successfully digitized over 6.1 million acres of farms, and can detect and monitor over 388 crops and 9400 crop varieties. Our solutions are location agnostic and have been used in over 52 countries, across diverse terrains and geographies. With a client retention rate of 98%, Cropin has met and exceeded the expectations of 225 clients around the world.

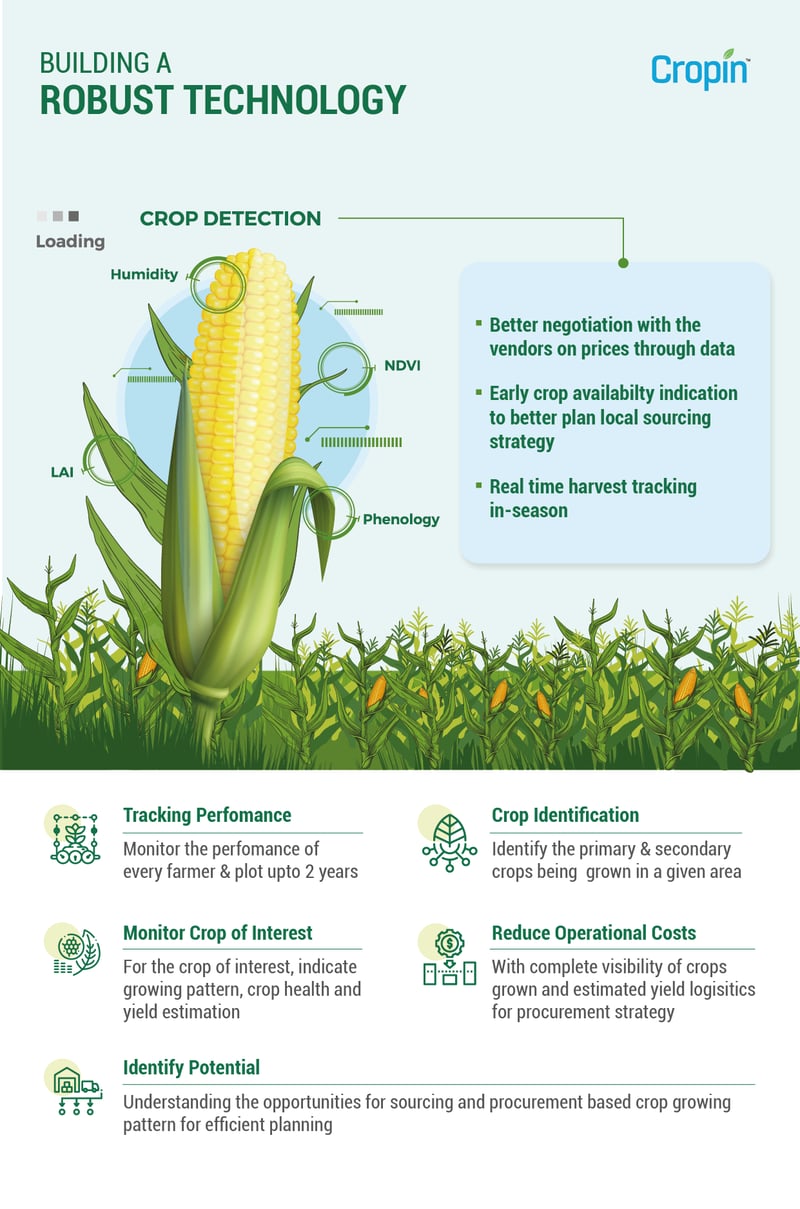

Leveraging satellite imaging technology has become paramount for food processing companies around the world today.

- With the right type of data intelligence monitoring to track the performance of every farmer & plot for the last 3 years.

- Identify the primary and secondary crops being grown in a given region. Receive complete visibility of crops grown & estimated yield – logistics for planning a procurement strategy.

Artificial Intelligence is Driving Procurement Strategies

By understanding the opportunities for sourcing and procurement-based crop growing patterns for efficient planning you will be better equipped for negotiation with vendors on prices, through data. With ‘early crop availability indication’ you’ll be able to plan a better local sourcing strategy across geographies. Obtain real-time reports of harvest in-season, and don’t waste a moment to get the best quality output and gain a competitive edge.

By understanding the opportunities for sourcing and procurement-based crop growing patterns for efficient planning you will be better equipped for negotiation with vendors on prices, through data. With ‘early crop availability indication’ you’ll be able to plan a better local sourcing strategy across geographies. Obtain real-time reports of harvest in-season, and don’t waste a moment to get the best quality output and gain a competitive edge.

With a one-stop integrated platform, monitor your key performance indicators through our easy-to-use dashboard and obtain insights and analysis on the go and receive only pertinent notifications in real-time.

Safeguarding and Creating a Long-term Sustainable Value Chain

If the quality of output is satisfactory and is approved for further processing, a slew of challenges wait for organizations post the production stage. Challenges like storage constraints, transportation issues, and accountability contribute to the infrastructure bottleneck, making the movement through the value chain difficult to track and manage. If even one of the stages compromises quality or breaches protocol, it would mean a tremendous loss of resources, time, and money, because the product is unfit to move forward or to be put on shelves for sale.

Given the complicated interconnectedness of the global supply chain, organizations find it hard to keep a track of the intricate and delicate network of logistics and various stakeholders involved. Does the question then become how to make it economically, environmentally, and socially sustainable?

This can be achieved by employing a data-driven Practice and leveraging the power of Big Data to create value in your local communities from which you source your raw materials, thereby, strengthening the local economies and improving agricultural systems to enhance food security and reduce the negative environmental impact.

With Cropin’s SmartRisk, this AI-led predictive solution, to map and detect crops – the acreage planted, the health of the crop and obtain a predicted yield report and analysis. Mitigate risks relating to raw material availability in their value chains and empower your local sourcing teams. You can also leverage Cropin’s solutions for obtaining a package of practices, climate-smart advisory, and water usage advisory, and strengthen your supply chain management to promote Global Compliance and Quality Standards.

With SmartWare access QR-code-based traceability to monitor the journey of your ingredients. With end-to-end traceability, get better visibility and marketability of your end product.

What can Food Processing Companies Do?

The current climate crisis, water scarcity, and the inevitable wastage food in the food processing value chain pushed some organizations to cut corners, which as history has shown, can be disastrous for the consumer and the brand.

Cropin is a trusted partner for many multinational enterprises, financial institutions, development aid agencies, and numerous governmental entities around the globe.