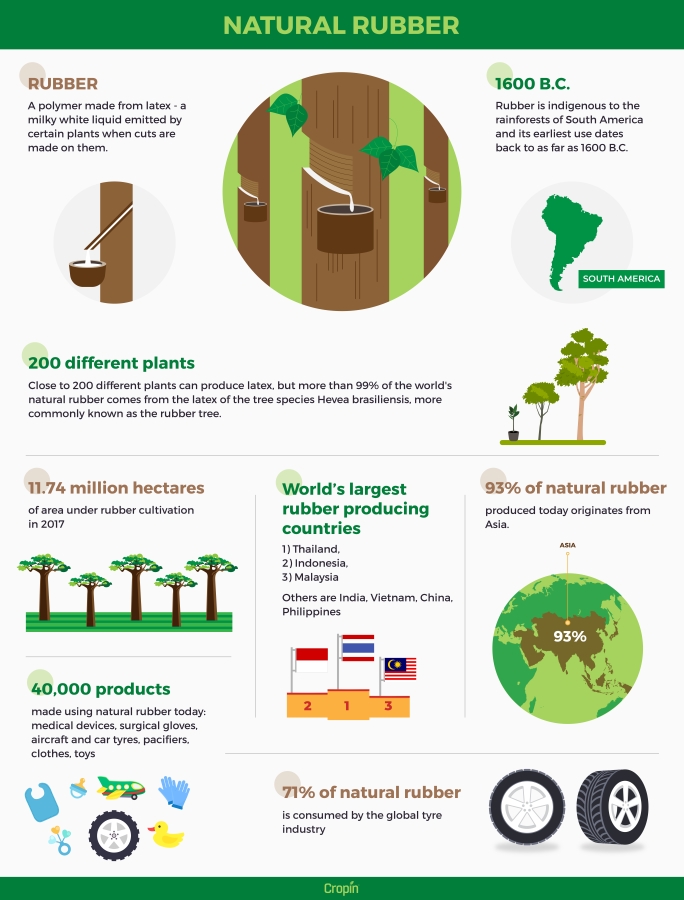

When we speak of ‘products made using rubber’, one can name at least a few dozen items, ranging from everyday items like pencil erasers, elastic bands, balloons, rubber ducks, and footwear, to car tyres, surgical gloves, tubes, pipes and hoses, and the like. Several physical and mechanical properties of rubber make it an extensively-used industrial commodity. Rubber is elastic but tough, can resist water, rust, corrosion and mould, and does not wear down easily. The discovery of vulcanisation in 1839 solved some of the challenges of using natural rubber by making it harder and more resistant to solvents, as well as improving existing qualities of elasticity, tensile strength, and abrasion resistance. Considering these properties, it is not surprising to know that natural rubber is a core component in the production of over 40,000 products, the most predominant of them being vehicle tyres. Recent estimates suggest that nearly two-thirds of the world’s natural rubber is used by the automotive industry to produce tyres, and with the number of cars on the road expected to double by 2050, one can expect a steady rise in the demand for this commodity in the years to come.

Present-Day Hurdles In Natural Rubber Production

The production of rubber is often associated with concerns regarding the sustainable cultivation of the trees, not very unlike that of oil palm. Some of these social and environmental issues include rapid and extensive deforestation causing the loss of biodiversity and the habitats of diverse endangered species of birds and animals, illegal expansion of plantations into natural forests, displacement of indigenous communities, and land-grabbing by large corporations.

More than 85% of the planet’s natural rubber originates from family-run plantations that cover only a few hectares of land area. The fluctuating and rather low market prices for natural rubber has resulted in considerable social and economic hardship to these individual owners. Consequently, this contributes to controversial labour practices in the industry, including long working hours and poor compensation for plantation workers, insufficient compliance with occupational safety standards, and even forced or child labour in many countries to meet the market demands. When these plantations don’t make enough profit, possibly also owing to the repayment of debt to traders, plantation owners are not motivated enough to invest in infrastructure or the resources to improve farm efficiency and quality of output.

A Collaborative Pursuit Of Sustainability In Natural Rubber Supply Chain

Bearing in mind the substantial role that several thousands of individual plantation owners play in the production of natural rubber, the onus of ensuring sustainable production of natural rubber rests upon them. It is, however, necessary to note that most of whom lack the knowledge or the resources to implement the right practices that will enable them to obtain more yield and also extend the lifespan of the trees. Nonetheless, with rising consumer awareness and the increasing demand for sustainable products, global enterprises are taking the necessary steps to procure only sustainably-produced raw materials. Several prominent automotive manufactures are also collaborating with NGOs to establish a natural rubber value chain that is fair, responsible, and sustainable.

In the year 2017, the CEOs of the World Business Council for Sustainable Development (WBCSD) Tire Industry Project (TIP) founded the Global Platform for Sustainable Natural Rubber (GPSNR). . This multi-stakeholder, international platform aims to drive socio-economic development in the natural rubber value chain by bringing together producers, processors, and traders of natural rubber, makers of tyres and other rubber-based products, car manufacturing companies, and various other downstream users. The GPSNR strives to uphold human rights, prevent land-grabbing, safeguard biodiversity and water resources, enhance yields, and improve transparency and traceability along the supply chain.

In the same vein, the Fair Rubber Association (FRA) aims to build on the concept of Fair Trade for products that are made from natural rubber. The FRA strives to provide primary producers with Fair Trade premium to incentivise the production of eco-friendly natural rubber, and consequently to improve the working conditions and livelihoods of plantation workers.

Digitising The Supply Chain For Better Transparency With CropIn

Faced with global demand for sustainable rubber products, several large corporations are committing themselves to improve transparency and sustainability throughout the rubber value chain, by collaborating with the different stakeholders to harmonise standards, uphold human rights, and preserve natural resources. In this endeavour, enabling technology solutions, such as Cropin, play a pivotal role in monitoring the progress by capturing critical data points at each stage of the supply chain. Starting from adherence to good agricultural practices and ensuring ethical labour practices at plantation-level, to increasing the visibility of operations from end to end, digital platforms go a long way in supporting the stakeholders achieve their goals..

Training and support for sustainable production of rubber

CropIn’s platform facilitates rubber-producing companies to sensitise plantation workers to climate-smart and sustainable cultivation practices, and monitor their progress to ensure the adoption of the same. CropIn also provides real-time agro-technical and agronomic advisories, supported by satellite-imaging and weather-based data, to reduce crop loss and optimise resource management. The organisation can configure activity schedules and the package of practices (POP) in CropIn’s SmartFarm® application, which can then be used by the agri-extension staff to guide the farmers in following the right practices for optimum yield. The knowledge that plantation workers gain through such training and advisories enables them to minimise improper or excessive use of agrochemicals and be better equipped to manage pests and crop disease.

Ensuring Ethical Labour

With CropIn’s mobile application, organisations can register the primary details of each plantation worker, including their name, photograph, proof of identity, and consent signatures to enable the organisation to verify that no child or forced labourers are employed in the plantations. Extension agents can also register the exact location of each plantation to establish the origins of every unit of the produce. Further, the management can pre-configure the protocols to track fair labour practices in the application, which can then be compared with the data that extension workers capture at ground level to ascertain that these practices are being adhered to.

End-to-End Traceability

CropIn’s traceability solution harnesses the data collected at every point of rubber production to increase transparency and visibility over farm operations. Producers can effectively monitor and regulate specific parameters that impact the environment, the safety and welfare of labourers, and the quality of yield. CropIn’s multi-stakeholder platform extends SmartFarm’s offerings beyond farm operations to facilitate traceability of produce beyond the point of harvest too. With the help of CropIn’s packhouse solution SmartWare®, each of the actors along the supply chain can add production details pertaining to their scope of operations, thus making end-to-end traceability possible for the end product.

Hassle-free Compliance and Certification

SmartFarm® permits enterprises to configure agricultural practices as recommended by certification bodies such as GLOBALG.A.P. or FairTrade, and digitally record each activity from start to end of production as per requirement. The exact geo-location of the plantations, details of plantation workers, protocols for workplace safety and employee welfare, and other pertinent information can be accessed by authorised users to prepare reports specifically for certification purposes. This functionality of CropIn significantly reduces the time and effort required to compile the information required to validate the organisation’s commitment to producing rubber sustainability in all aspects.

Monitoring Land Usage

In addition to the data collected at ground-level, governments, NGOs, and other key stakeholders can leverage CropIn’s AI/ML-powered engine SmartRisk® to map historical land usage based on satellite-imaging data. SmartRisk’s proprietary algorithms deliver insights that will help the stakeholders to identify if primary forests have been cleared by rubber producers to allow for the expansion of plantations. Corporations can benefit from this intelligence to verify claims of sustainable production and make the right decisions to source from plantations that do not have a negative impact on the environment. On the other hand, government entities can monitor the change in land usage to apprehend organisations that do not adhere to sustainable practices.

Enhanced Livelihoods of Plantation Workers

Thanks to increased levels of consumer awareness and the global effort to drive sustainable rubber production, certifications for sustainably produced products can now fetch a premium price, which can improve incomes and livelihoods for plantation workers. With an increase in market prices, plantation owners would also be encouraged to improve the infrastructure in the plantation and provide better facilities for the employees. When end-consumers refuse to buy from sources that do not employ socially and environmentally sustainable practices, rubber producers will be compelled to adopt practices that will attract buyers. Collectively, the collaboration of all stakeholders towards the same goal will guarantee better livelihoods for millions of plantation workers globally.

Take part in the global campaign for ethically- and sustainably-sourced natural rubber. Get in touch with us today to explore how CropIn can strengthen your initiatives.